After Sales Support

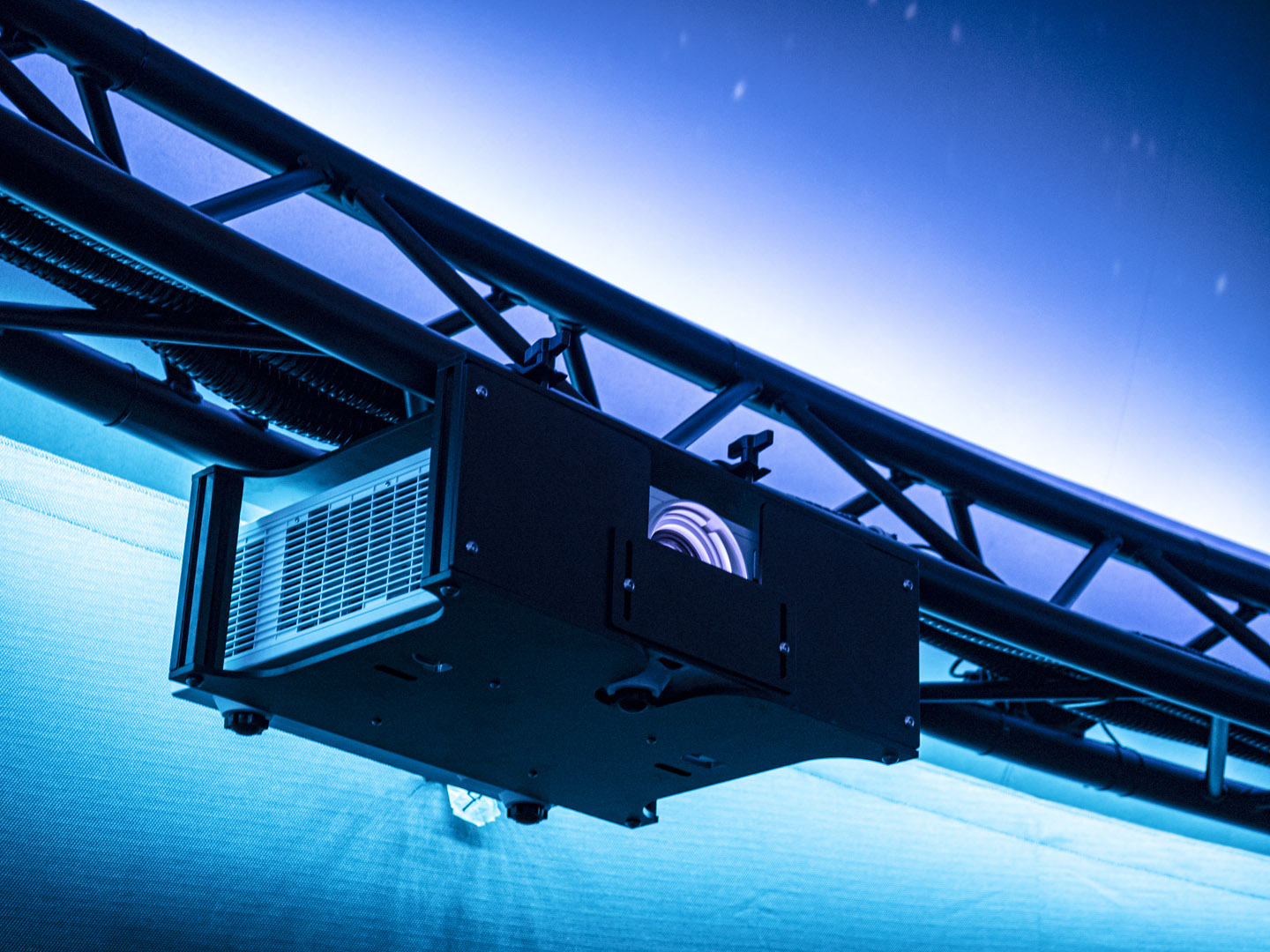

Fulldome.pro provides support to ensure clients have everything they need to get the most from their domes and projection systems

Menu

Every Fulldome.pro project includes a one-year warranty against defects in materials and workmanship.

In addition, we offer free, online post-sale support for the whole year, and the opportunity to purchase extended warranties and support services.

Many hours of research and development have made Fulldome.pro technology intuitive and easy to use. In-person end-user training is included during or after installation and comprehensive operation manuals are provided. These factors combine to make sure your team is ready to operate and maintain the dome from day one. Refresher training can be provided for new staff if required.