How solid screens transitioned into next generation easy to install solution?

For as long as there have been planetariums there have been dome screens. That means that the history of dome screens started with the first Zeiss planetarium projection in 1923.

How the story began

Initially, screens were solid plaster inside a concrete dome shell — a permanent part of the building. More recently perforated aluminum screens have been used in fixed planetariums around the world. But neither of these are portable, and both are expensive.

Why did we develop new screen technology?

- to make the installation process faster & easier;

- to reduce screen weight;

- to make dome more affordable.

How do we use negative-pressure technology to make perfect screen almost anywhere?

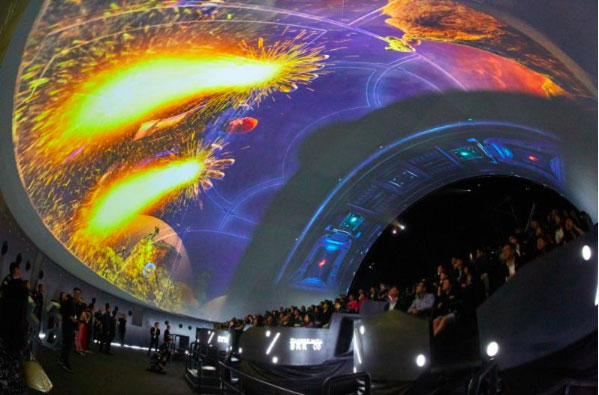

Fulldome.pro use our patented negative‑pressure technology to make light-weight, yet high-quality projection screens that can be fitted into existing domes, be part of a new dome, or even a mobile dome.

Regular shaped screens

After we construct the dome frame, we stretch a cover over the outside and suspend a fabric screen inside the dome.

Three steps to form the perfect screen

- Connect the cover and the screen: connect the cover and the screen around the base of the dome, leaving the frame inside the closed envelope.

- Switch on the screen: use fan to suck the air out from between the screen and the cover, creating negative pressure.

- Wait till the screen is formed: the higher atmospheric pressure outside of the envelope pushes the cover inwards over the frame and pushes the screen outwards, towards the frame.

Little secrets to make the perfect screen

Because it has been precisely sewn to be smaller than the frame, the screen remains suspended inside the dome forming a perfect hemispherical projection surface. Once the screen is in shape, we can switch the fan to a lower speed, using less electricity and making it quieter too. For big domes, we often use more than one fan to evacuate the air faster, but once the screen has formed, we can turn all but one fan off.

What about an irregular shape or frameless screen?

In 2018 we developed a new process to make a negative-pressure screen with an external frame or no frame at all. This means we can make the screen in different shapes, not just a dome. This new process is how we made the irregular shaped screen for The Marvel Experience Thailand.

Negative-pressure technology in numbers

- time to form the screen: around 2 minutes for a 3M dome, 20 minutes for an 8M dome;

- weight of the screen: from 3kg for a 3M dome, 25kg for an 8M dome;

- pressure between the screen and the cover: 100-200 Pascals (what is 1/1000 of the pressure in a car tire);

- fan power consumption to maintain pressure: around 40 Watts;

- fire safety compliance: all fabrics have been certified fire retardant;

- noise from the fan during the forming screen: about 35dB;

- noise from the fan during usage: about 30dB.

Next time we will tell more about our innovative technology about the negative-pressure dome. Stay connected to learn more!